Wolverhampton is said not to be in the Black Country (unlike the nearby chain making town of Dudley), rather it is surrounded by Black Country coal fields. Like many towns in the West Midlands it business was metal, in the case of Wolverhampton locks and the name Chubb appears in early records. Another early name was Mander connected with the production of lacquer and known later for paint. Stretching back further, like many English towns, the wool trade dominated.

The West Midlands was well served by turnpike roads, but the advent of the canals opened the area to much needed bulk shipment. The commercial imperative was to get coal into nearby Birmingham, but the movement of finished goods and supplies of raw materials to other towns like Wolverhampton was important.

In his entertaining History of Wolverhampton, Chris Upton tells the convoluted story of the West Midlands canals. Much comes down to the terrain and geology. Towns were often built on hills and so canals would either need to tunnel under them or use precious water to climb and descend in flights of locks. James Brindley was the surveyor for the Staffordshire & Worcestershire canal which was the first to serve Wolverhampton in 1772. The Birmingham canal followed, also under Brindley. The problems were not so much technical as commercial, as canal companies competed with the amounts they charged users. Other canals followed, some much later under Thomas Telford, until a network was built that allowed Birmingham to claim more canals than Venice. The coming of the Birmingham, Wolverhampton and Stour railway marked the beginning of the end for the canals as arteries of commerce, but of course opened up the area to further commercial advantage.

Wolverhampton may not have had coal mines, but it did have its specialist ironmasters and ironmongers, dealing in cheaper goods, who would supply metal to workshops and then take finished products for resale. Upton suggests that workshops were nearly always small, but that the work of the ironmongers made it, taken as a whole, mass production. In relation to the more specialised ironmasters, who were more often to be found in nearby Rugeley and Bewdley, their production would be worked into high quality locks and scythes. One manufacturer, William Wood, extended his skills into copper coinage for America. In time, manufacture began to match that of Birmingham with buttons, shoe-buckles and watch chains. In terms of mechanisation, it is said that one of the first Newcomen engines for Mr Back of Wolverhampton. Chubb moved their lock making business from Hampshire and built the Chubb Lock Works. Chubb expanded their business into fire security and bought among other Pyrene a name that had appeared elsewhere in this story. The enlarged Chubb went through a number of ownerships but is at the time of writing a British public company.

The railways would point the way for manufacturing in Wolverhampton as the GWR selected the town for their northern workshop. Here were manufactured mainly tank engines, but there was also a repair facility making it a close rival to Swindon. In terms of ‘independents’, Henry Meadows supplied gear boxes and petrol and diesel engines. The railways served major local manufacturers including steel makers Stewarts & Lloyds at Horseley Fields and Bilston. The scene must have been similar to Sheffield with blast furnaces, forges and crucibles. Wolverhampton featured in the Great Exhibition of 1851.

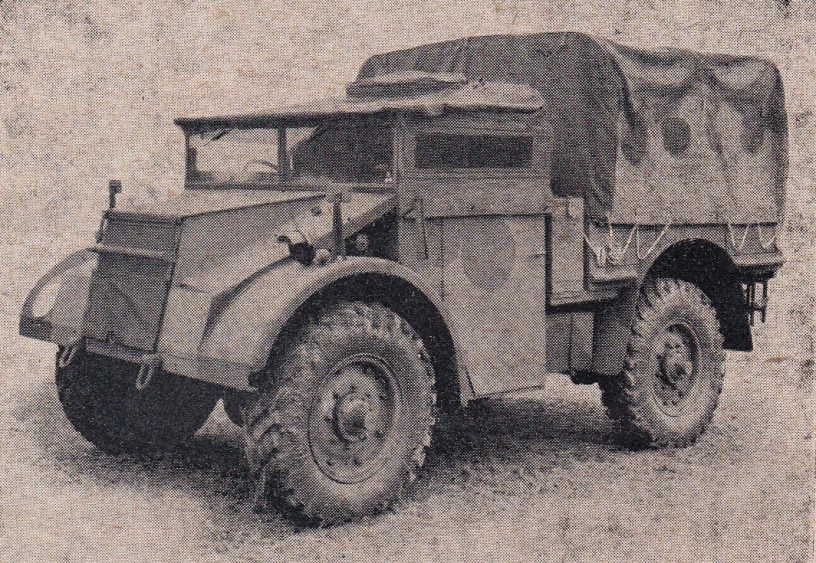

Following on from railways came bicycles where Wolverhampton and companies like Rudge and Sunbeam competed with the larger cycle sector in Coventry. Sunbeam run by John Marsden moved from cycles to motor cars and became a major employer in the town with their Sunbeamland Works. It became famous for its very fast cars, synonymous with names like Malcolm Campbell. Sunbeam would later join the Rootes Group. Other Wolverhampton companies included Guy Motors, the founder of which Sydney Guy had been works manager at Sunbeam, which would in wartime produce vehicles for hauling heavy guns (as shown in the image). Guy developed its Ant into a 4×4 Quad Ant which, for the duration of the war, would be the field artillery tractor of choice for 25 pounder guns. Derived from the design of the Quad Ant was an armoured car with revolutionary welded armour plate. The demand for this outstripped Guy’s capabilities, and Humber took the design and produced some thousands for the War Office. Guy was later bought by Jaguar. I write more about Guy Motors and manufacturers of military vehicles more generally in War on Wheels.

Joseph Sankey were suppliers to the motor industry and they became part of GKN. Sankeys had been formed in nearby Bilston in 1854 manufacturing japanned metal goods. The advent of the electric motor introduced a new product, electrical laminations for the for the armatures of dynamos. The product developed and Sankey were supplying Crompton and Brush amongst others. The core business was pressings and these found favour with motor vehicle manufacturers including Austin, Morris, Humber and Daimler. In time more space was needed and this was found at Hadley Castle near Telford. Uses for metal pressings were found in the new radio manufacturing industry and in metal office furniture. In 1919, George Sankey, having lost his son in the First World War, agreed to a takeover by the Wolverhampton firm of Lysaghts. Soon after, the enlarged Lysaghts joined GKN. I write of this in How Britain Shaped the Manufacturing World.

Aircraft manufacture also figured with Boulton and Paul, later Dowty Aerospace. H.M. Hobson made carburettors for aircraft and undertook the management of two shadow factories in the Second World War. It later became part of Lucas Aerospace. The American Goodyear set up tyre production in the town. Motor cycles featuresd with Villiers as boiler making did with John Thompson of which I write in Vehicles to Vaccines and which played a big part in nuclear power stations. The Electric Construction Company was another big employer specialising in generators. They later became part of Hawker Siddeley. It wasn’t only metal, Courtaulds built a factory to produce rayon and employed some 3,600 in 1936. Tarmac also had a presence in the town.

Glywed was formed in 1939 by the merger of Glynn Brothers lead manufacturers of Birmingham and the Wednesbury Tube Company. Based in Bilston they made copper and steel tubes, polythene tube, lead pipe and plate, steel bar and fittings. Over the years they added further metal manufacturing companies including Allied Iron Founders which had been formed in 1929 bringing together a dozen iron founders in Falkirk, Stockton and Stafforshire including the Coalbrookdale company. In the same year the Aga Cooker came to Smethwic from Sweden. The new company Aga Heat floated in 1934 and in 1935 was bought by Allied Ironfounders. Allied Ironfounders was bought by Glywed in 1969. The manufacture of Agas moved to Leamington but there is evidence that the casting of the Aga parts was undertaken at Coalbrookdale. Courtaulds set up a plant in the town to manufacture viscose-yarn. I write more on this in the blog on Coventry.

As with so many British towns, the major employers now are retailers. An exception is the American Collins Aerospace which can trace its origins back to Lucas.

Take a look at my books How Britain Shaped the Manufacturing World and Vehicles to Vaccines which look at the history of British manufacturing sector by sector and chronologically.

Further reading:

- Chris Upton, A History of Wolverhampton (Chichester: Phillimore, 1998)

- Edgar Jones, A History of GKN volume II, The Growth of the Business 1918-1945 (London: Macmillan, 1990)

http://www.historywebsite.co.uk/Museum/metalware/sankeys/sankey01.htm