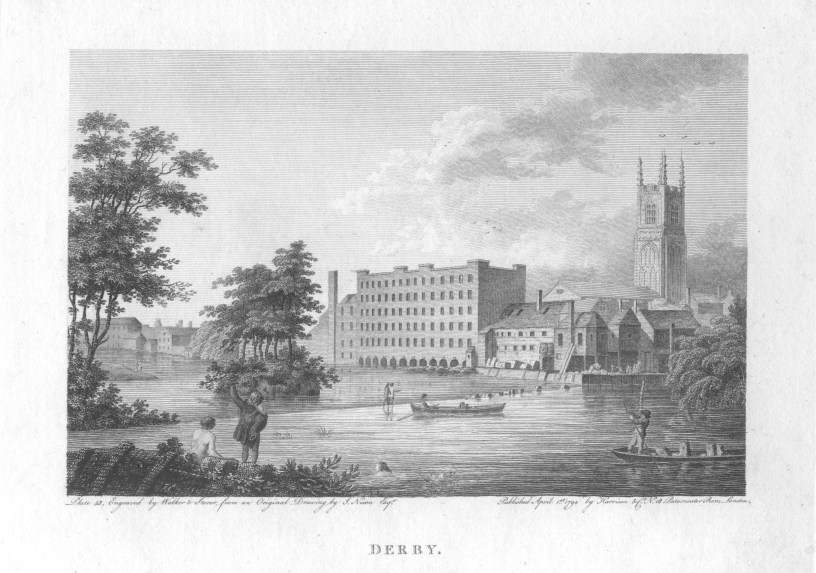

The city of Derby is a home of British engineering and of probably the first textile factory at the Silk Mill. This has been repurposed to tell Derby’s story. The entrance picks up one of the earliest contributions in the Silk Mill itself, an early example of the factory manufacturing system, taken further fifty years later by Arkwright at Cromford Mill. The image is of the mill with thanks to the museum.

Evelyn Lord, in her book Derby Past, writes of the silk industry arriving in Derby with skills learnt in Italy and business acumen from London. The industry prospered and by the end of the 18th century there were twelve mills in town producing silk thread for a nation demanding ever greater quantities of thread for a booming textile industry. There was a link to framework knitting as I tell in my blogs on Leicester and Nottingham manufacturing. A particular Derby contribution was the invention by Jedidiah Strutt of the Derby rib attachment which allowed knitted garments to have both knit annd purl stitches. The recession of the 1830s caused hardship in Derby as elsewhere as demand dropped. There followed industrial unrest and then foreign competition causing the industry to shrink.

The other Derby industry from the days before the Industrial Revolution was china where the art of a Huguenot refugee combined with the practical skills of a Staffordshire potter to combine in what would become the Crown Derby Porcelain Company.

The 18th and early 19th century witnessed in Derby what was going on elsewhere. In Derby’s case it was a canal linking to the Trent and Mersey canal to the south of the city, turnpike roads and, reflecting the military threat from Napoleon, an Ordnance Depot on Normanton Road. I write below of its much larger successor in Sinfin Lane for the Second World War.

The canals opened up the Derbyshire coal fields to the Birmingham market. The railways were yet more ambitious linking Derby not only north and south but east and west with what became the Midland Railway promoted by George Hudson, the ‘railway king’.

The station at Litchurch in Derby initially served three railway companies: the Midland Counties, the North Midland and the Birmingham and Junction Railway which combined in the Midland. Each company had its own workshops and round house with a central turntable and these too were combined.

The combined workshop designed and built the first Derby manufactured locomotive in 1851. It also produced the first steel rail which was laid to the north of Derby. By 1855, 33 engines had been produced. The workshops pursued technical innovation and produced talented engineers some of whom moved to the workshops of other railway companies. It became and its successor still is a major employer. Long established Derby printer Bemrose produced the timetables for the new railways.

A fourth railway came to the town in the 1870s. The Great Northern linked Uttoxeter, Derby and Nottingham to the Erewash valley and so the Butterley Iron Works at Ripley and the Cromford textile mill. Whereas the first railway station had been built away from the town centre and so left intact much of Derby’s architectural heritage, the Great Northern demolished great swathes in order to reach the new station at Friar Gate. This station closed in 1964 and that at Litchurch continues to thrive.

The railways brought prosperity to the town and its businesses. Handyside’s iron works produced the iron work for many of the Midland Railway stations as well as a good number of great structures overseas. In 1862, the railways employed 2,000 and this number doubled in the years to 1892. The population of Litchurch increased from 35 in 1801 to 6,560 in 1861.

The railway workshops continued as part of British Railways and where then transferred into a company BREL prior to privatisation. It was the Swiss ABB together with Trafalgar House and the BREL management team which took BREL into the private sector in 1989. Trafalgar House and Management were later bought out by ABB which then merged with Daimler-Benz, eventually to be bought by the Canadian Bombardier. The workshops are now part of Alstom.

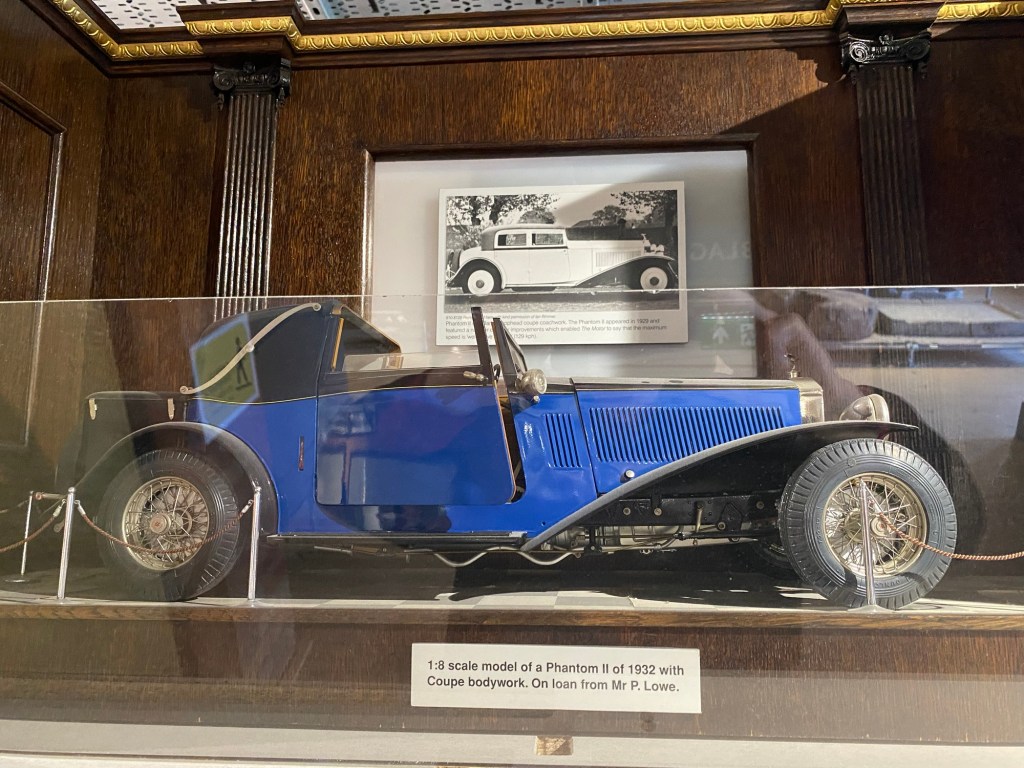

Electricity made its presence felt in the town at the beginning of the 20th century with the coming of electric trams. I had read that it was the availability of electricity that attracted Rolls-Royce to the city. Lord suggests that it was a combination of factors put forward by the Derby Development Committee that gave the town the necessary advantage over competing sites in Manchester, Leicester, Bradford and Coventry. These factors included the availability of coal and iron, the presence of foundries to produce the steel for the motor cars, and low wages compared to Manchester and Bradford. I write of the early years of the company in How Britain Shaped The Manufacturing Word and of its later development in Vehicles to Vaccines.

Derby in the Second World War saw Rolls-Royce designing and producing aero engines including the famous Merlin. The LMS works assembled and repaired Spitfires and Hurricanes as well as producing Horsa gliders, Bailey bridges and field guns. Qualcast made grenades. Quality Castings had been set up by Vincent Jobson, son of John Jobson of Sheffield who had set up the Derwent Foundry. Vincent believed that there was a market for lawn mowers and these were made by Qualcast until 1991.

The Museum of Making takes the visitor through the astonishing array of manufacturing activity carried on in this midlands city really from the eighteenth century onwards. The museum has one floor titled simply assemblage and they suggest that this looks more like a museum store than a curated display. These photographs help to give a flavour

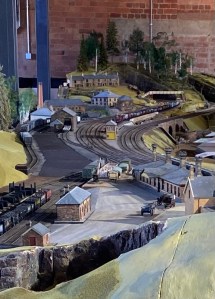

The railways are the subject of many exhibits from rails, signals to telegraph equipment, but no locomotives (you need to go to York for them). There are mock ups from the Derby railway workshops, not least the Intercity 125. It is clear that the Midland Railway based in Derby was a leader.

Lawnmowers tell of the presence in the city of Qualcast. Fashion wear speaks of the ground breaking work in artificial fibres at British Celanese, later part of Courtaulds. There are a number of electrical equipment manufacturers. Ceramics feature with industrial examples on display; Crown Derby and Denby will be found elsewhere.

There is a Rolls-Royce aero engine suspended from the roof and information boards telling the story of this, the city’s most illustrious son. There are on display models of Hawk and other famous engines.

Derby did its job in war time in addition to Rolls-Royce Merlins, there was a huge army Motor Transport depot. It also did its job for electricity generation with boiler makers International Combustion also in Sinfin Lane.

Further reading

You can read more in my books How Britain Shaped the Manufacturing World and Vehicles to Vaccines

Derby Past, Evelyn Lord, (Chichester: Phillimore, 1996)